Chilli Cleaning Machine

Best Suppliers for Chilli Cleaning Machines in India Saansaa’s Quality Solutions

Saansaa Machines Pvt Ltd is a trusted name among the best suppliers for chilli cleaning machines in India, offering top-quality and efficient solutions tailored for commercial and industrial use. Our chilli cleaning machines are designed using advanced technology to ensure precise, effective, and hygienic cleaning of chillies, enhancing productivity and maintaining quality standards. As an industry leader, we provide affordable and reliable equipment that meets the diverse needs of chilli processing businesses across India. Choose Saansaa for cutting-edge technology, exceptional customer support, and machinery that boosts your operational efficiency.

Chilli Cleaning Machine Manufactures in India

With years of experience in the chilli industry, Saansaa Machines Pvt Ltd has honed its expertise in manufacturing top-quality chilli processing machinery. Starting with our renowned Chilli Stem Cutting Machine, we established ourselves as industry leaders committed to innovation and excellence. Building on that success, we now offer state-of-the-art Chilli Cleaning Machines, designed to transform your processing operations with efficiency and precision. As one of the leading Chilli Cleaning Machine Manufacturers in India, we are dedicated to delivering equipment that meets diverse industry needs, ensuring quality, reliability, and customer satisfaction at every stage. Choose Saansaa for unmatched expertise and advanced solutions that elevate your busines

Best Chilli Cleaning Machine in India: Our chilli cleaning machines are renowned for their quality and performance, making them the best choice for chilli processing across India. They deliver efficient cleaning, removing dust, stems, leaves, and other impurities with ease to ensure premium quality output.

Chilli Cleaning Machines for Sale in India: We offer a range of chilli cleaning machines for sale, tailored to meet various business needs. Whether you’re a small-scale or large-scale processor, our machines are designed to boost productivity and provide consistent results, ensuring the best value for your investment.

Automated Chilli Cleaning Machine Manufacturers: As industry-leading manufacturers, we specialize in automated chilli cleaning machines that reduce manual labor and enhance operational efficiency. Our machines use advanced technology to streamline the cleaning process, saving time and increasing overall production capacity.

Advanced Chilli Cleaning Machine Suppliers in India: We are one of the top suppliers of advanced chilli cleaning machines in India, providing cutting-edge solutions equipped with the latest technology. Our machines are engineered to deliver precise cleaning results, ensuring superior quality for all your chilli processing requirements.

Load the chilli material onto the feeder section of the machine. Simply lay the chilies on the trough, enabling a smooth entry into the machine drums for processing.

During this process dry red chilli gunni bags are loaded into feeding conveyor hopper and it moved towards drum cleaner. The cleaner is designed to remove dust, sand, micro stones and customized to capture threads. Next cycle is synchronized with drum and chilli moves towards weight and density based cleaning which works on technology of air conveying where we customize the equipment to handle and separate different impurities like stones, mud balls, plastic, paper pieces and many more at different points. Finally material moves towards output section through cyclone.

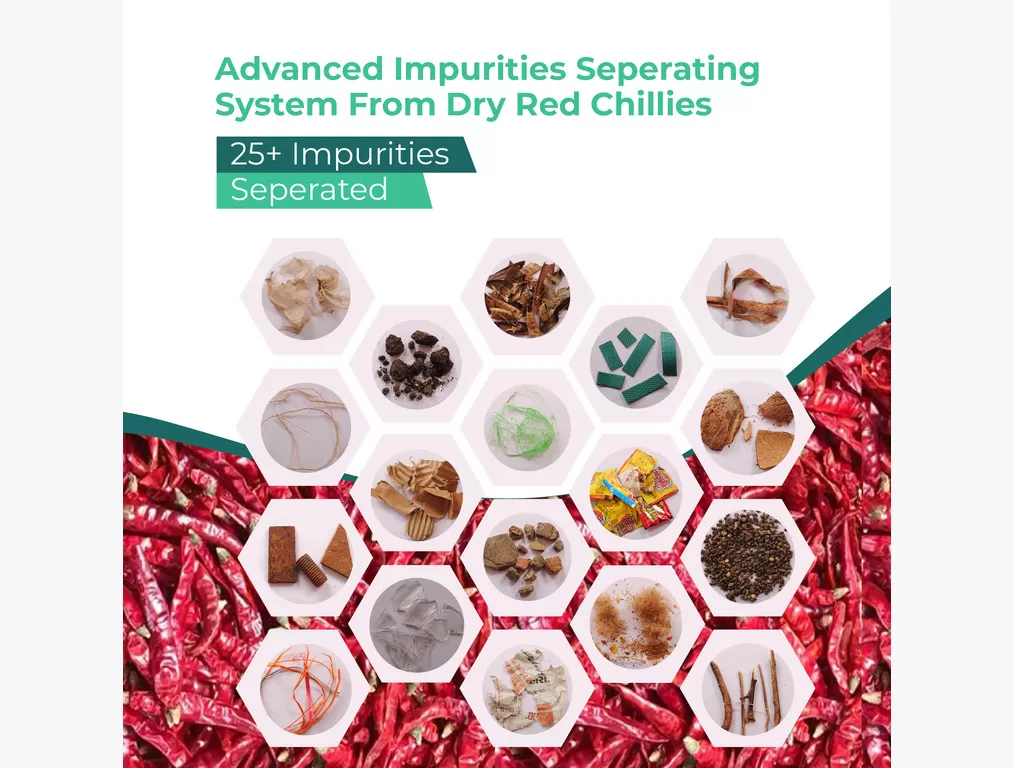

Impurities which are inside chilli are removed at different stages as described in processing section. Major impurities which are dust, sand and stone are removed in drum cleaner section. Light impurities like feather, paper, plastic, jute dust, gutka pouches etc are removed in first stage of aspiration. Heavy impurities like stones, mud balls, glasses, metal are removed during second stage of aspiration attached with magnetic separation system. Furthermore, seeds are managed separately towards seed separator as per application by user.

Final output of cleaned chilli is moved towards further process. If it is for trading purpose, we provide gunni bag filling system. If it is for further grinding purpose, we connect output towards grinding unit by conveyor. If need to have further stem cutting process, it is moved towards our stem cutter section. Everything is customized as per user application.

Load the chilli material onto the feeder section of the machine. Simply lay the chilies on the trough, enabling a smooth entry into the machine drums for processing.

During this process dry red chilli gunni bags are loaded into feeding conveyor hopper and it moved towards drum cleaner. The cleaner is designed to remove dust, sand, micro stones and customized to capture threads. Next cycle is synchronized with drum and chilli moves towards weight and density based cleaning which works on technology of air conveying where we customize the equipment to handle and separate different impurities like stones, mud balls, plastic, paper pieces and many more at different points. Finally material moves towards output section through cyclone.

Impurities which are inside chilli are removed at different stages as described in processing section. Major impurities which are dust, sand and stone are removed in drum cleaner section. Light impurities like feather, paper, plastic, jute dust, gutka pouches etc are removed in first stage of aspiration. Heavy impurities like stones, mud balls, glasses, metal are removed during second stage of aspiration attached with magnetic separation system. Furthermore, seeds are managed separately towards seed separator as per application by user.

Final output of cleaned chilli is moved towards further process. If it is for trading purpose, we provide gunni bag filling system. If it is for further grinding purpose, we connect output towards grinding unit by conveyor. If need to have further stem cutting process, it is moved towards our stem cutter section. Everything is customized as per user application.